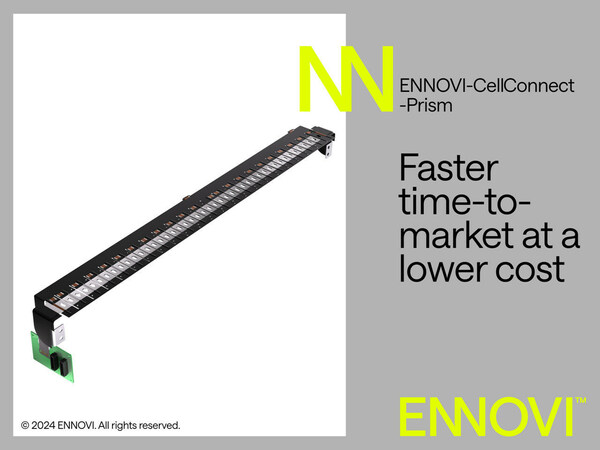

Supports the robust connection of individual prismatic cells with the flexibility to create larger modules or advanced cell-to-pack and cell-to-chassis configurations while streamlining the assembly process and optimizing material costs

SINGAPORE, March 6, 2024 /PRNewswire/ -- ENNOVI, a mobility electrification solutions partner, announces the launch of ENNOVI-CellConnect-Prism, a groundbreaking prismatic battery cell contacting system designed to redefine the connectivity and efficiency of battery modules.

ENNOVI-CellConnect-Prism empowers engineers with unparalleled flexibility, enabling the seamless integration of individual prismatic cells to create larger battery modules or advanced cell-to-pack (CTP) and cell-to-chassis (CTC) configurations. By streamlining the assembly process and eliminating inefficiencies, ENNOVI-CellConnect-Prism accelerates battery pack production while optimizing material usage and reducing costs.

Randy Tan, Product Portfolio Director for Battery Platform Development Solutions, ENNOVI, explains, "Traditionally, prismatic cell contacting systems have relied on current collector assembly (CCA) technologies, which often suffer from inherent inefficiencies. These systems entail complex processes, including laminating and assembling carriers with low-voltage data collection circuits, current collectors, and terminal busbars. However, ENNOVI-CellConnect-Prism revolutionizes this approach by introducing innovative features that enhance performance and sustainability."

One of the key innovations of ENNOVI-CellConnect-Prism is the adoption of a die-cut circuit (FDC) as an alternative to the conventional flexible printed circuit (FPC). This reel-to-reel process reduces production time and costs while minimizing environmental impact. Additionally, the use of automotive-grade PET material and hot-bar soldering ensures optimal thermal resistance and component attachment without compromising integrity.

Furthermore, ENNOVI-CellConnect-Prism eliminates the need for traditional insulation methods by integrating voltage and temperature sensing directly into the assembly. This approach optimizes material usage and production efficiency while maintaining the highest standards of reliability and safety.

ENNOVI's patent-pending ENNOVI-CellConnect system represents a paradigm shift in battery interconnect technology, empowering OEMs and gigafactories to scale production and meet the growing demand for electrified mobility solutions. Compatible with prismatic, cylindrical, and pouch cell formats, this versatile platform offers unique customization options for diverse applications.

For more information on the new ENNOVI-CellConnect-Prism, please visit: https://ennovi.com/cell-contacting-system-prismatic

About ENNOVI:

ENNOVI, a Mobility Electrification Solutions Partner, is a world leader in designing and manufacturing customized interconnect and high-precision system solutions for electric vehicles. The company is fully dedicated to the mobility market with the agility to act at speed in realizing EV OEMs' needs, from product, process, and manufacturing, on a global level. ENNOVI is accelerating EV market customers' ideas and requirements through end-to-end competencies in battery platform, power and signal interconnect needs. Headquartered in Singapore, ENNOVI has more than 10,000 employees across 15 sites globally, where all its activities are socially responsible, with minimal environmental impact. ENNOVI. Electrify faster. Learn more at www.ennovi.com.

Press Contacts:

ENNOVI

Selvan Wilhelm

Selvan.Wilhelm@ennovi.com

Agency Contact:

Publitek US

Erin McMahon

erin.mcmahon@publitek.com

Publitek Germany

Carsten Otte

carsten.otte@publitek.com

1 year ago

264

1 year ago

264

English (United States)

English (United States)