Coronus® DX builds on Lam's 15-year heritage of innovation in bevel solutions

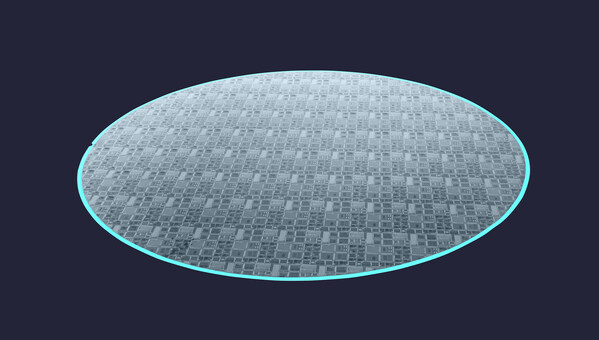

FREMONT, Calif., June 27, 2023 /PRNewswire/ -- Lam Research Corp. (Nasdaq: LRCX) today introduced Coronus DX, the industry's first bevel deposition solution optimized to address key manufacturing challenges in next-generation logic, 3D NAND and advanced packaging applications. As semiconductors continue to scale, manufacturing becomes increasingly complex with hundreds of process steps needed to build nanometer-sized devices on a silicon wafer. In a single step, Coronus DX deposits a proprietary layer of protective film on both sides of the wafer edge that helps prevent defects and damage that can often occur during advanced semiconductor manufacturing. This powerful protection increases yield and enables chipmakers to implement new leading-edge processes for the production of next-generation chips. Coronus DX is the newest addition to the Coronus® product family and extends Lam's leadership in bevel technology.

"In the era of 3D chipmaking, production is complex and costly," said Sesha Varadarajan, senior vice present of the Global Products Group at Lam Research. "Building on Lam's expertise in bevel innovation, Coronus DX helps drive more predictable manufacturing and significantly higher yield, paving the way for adoption of advanced logic, packaging and 3D NAND production processes that weren't previously feasible."

Deposition Adds Critical Protection During Process Integration

Complementing Coronus bevel etch technology, Coronus DX is a game-changer for chipmakers by enabling new device structures. Repeated layers of processing can cause residues and roughness to accumulate along the wafer edge where they may flake off, drift to other areas, and create defects that cause a semiconductor device to fail. For example:

When those defects cannot be etched away, Coronus DX deposits a thin dielectric layer of protection on the bevel. This precise and tunable deposition helps resolve these common issues that may impact semiconductor quality.

"CEA-Leti applied its expertise in innovative, sustainable technology solutions to help Lam Research tackle key challenges in advanced semiconductor manufacturing," said Anne Roule, head of the Semiconductor Platform Division at CEA-Leti. "By simplifying 3D integration, Coronus DX drives significantly higher yield and enables chipmakers to adopt breakthrough production processes.

Proprietary Process Drives Yield Improvement

Coronus DX enables best-in-class precision wafer centering and process control, including integrated metrology, to ensure consistency and repeatability of the process. Coronus products incrementally increase wafer yield, delivering an additional 0.2 to 0.5 percent of yield per etch or deposition step, which can result in up to 5 percent improvement across the wafer flow. Manufacturers running more than 100,000 wafer starts per month may yield millions of extra die with Coronus – potentially worth millions of dollars – over the course of a year.

Every Major Chipmaker Uses Coronus

First introduced in 2007, the Coronus product line is used by every major semiconductor manufacturer, with several thousand chambers installed globally. Lam's Coronus product family is the industry's first mass production-proven bevel technology. Its Coronus and Coronus HP solutions are etch products designed to prevent defects by removing layers along the edge. Coronus solutions are used in the manufacturing of logic, memory and specialty devices, including leading-edge 3D devices. Coronus DX is now being used in high-volume manufacturing at leading customer fabs around the world.

"Improving quality in the production process through advancements in areas such as bevel technology is essential to our ability to provide next-generation flash memory at scale to our customers," said Hideshi Miyajima (Ph.D.), Technology Executive of Memory Process at Kioxia Corporation. "We look forward to continuing to work with Lam Research and its Coronus solutions to enable leading-edge wafer production."

"In a complex manufacturing environment, increasing die yield is critical to maximizing fab productivity" said Andrew Goh, corporate vice president and general manager, Southeast Asia at Lam Research. "Close collaboration with our customers is critical in developing innovative solutions like Coronus DX and driving improvement in chipmakers' production processes."

Media Resources

Visit the Lam Newsroom to access a related image. Read the Lam Blog. Learn more about Lam's bevel deposition research with CEA-Leti.About Lam Research

Lam Research Corporation is a global supplier of innovative wafer fabrication equipment and services to the semiconductor industry. Lam's equipment and services allow customers to build smaller and better performing devices. In fact, today nearly every advanced chip is built with Lam technology. We combine superior systems engineering, technology leadership, and a strong values-based culture, with an unwavering commitment to our customers. Lam Research (Nasdaq: LRCX) is a FORTUNE 500® company headquartered in Fremont, Calif., with operations around the globe. Learn more at www.lamresearch.com.

Caution Regarding Forward-Looking Statements

Statements made in this press release that are not of historical fact are forward-looking statements and are subject to the safe harbor provisions created by the Private Securities Litigation Reform Act of 1995. Such forward-looking statements relate to, but are not limited to: the complexity of chip manufacture, the effect that the Coronus DX can have on predictable manufacturing, on yield and on the adoption of new processes and new device structures used in chip production; the cause and effect of residues or roughness on the wafer edge; the need for predictable results to drive yield enhancement; the percentage of yield improvement per etch or deposition step, as well as the total yield improvement across the wafer flow; the potential number and value of the extra die produced, and Lam's leadership in bevel technology. Some factors that may affect these forward-looking statements include: the semiconductor products (such as chips or die) being produced and their volume and complexity; the processes being used in that production; the use of Lam's Coronus tools and the frequency of that use, and operating conditions in the facility where the chips are being produced as well as the other risks and uncertainties that are described in the documents filed or furnished by us with the Securities and Exchange Commission, including specifically the Risk Factors described in our annual report on Form 10–K for the fiscal year ended June 26, 2022 and our quarterly reports on Form 10-Q for the fiscal quarters ended December 25, 2022 and March 26, 2023. These uncertainties and changes could materially affect the forward-looking statements and cause actual results to vary from expectations in a material way. The Company undertakes no obligation to update the information or statements made in this release.

Company Contacts:

Allison L. Parker

Media Relations

(510) 572-9324

publicrelations@lamresearch.com

Ram Ganesh

Investor Relations

(510) 572-1615

investor.relations@lamresearch.com

Coronus® DX deposits a proprietary layer of protective film on both sides of the wafer edge to help prevent damage.

1 year ago

253

1 year ago

253

English (United States)

English (United States)