|

SINGAPORE, Oct. 27, 2023 /PRNewswire/ -- tesa, an international manufacturer of adhesive tapes and self-adhesive solutions, officially opened its new site in the Vietnamese port city of Haiphong today. The new site is part of tesa's strategic orientation to regionalise production. It expands the regional production capacity and optimises the supply chains to ensure reliable regional availability of both its products as well as transport capacities and the procurement of raw materials.

tesa currently operates 13 production sites worldwide, including large plants in Germany (Hamburg, Offenburg), Italy, the USA and China. The new site in Haiphong is approximately 70,000 square metres in size and has a production capacity of around 40 million square metres of adhesive tape per year, perfectly complementing the existing production site in Suzhou, China which opened in 2005. The additional production capacity will primarily serve the fast-growing Asian market, especially in the automotive and electronics industries.

In the first phase, about 130 employees will work at the Haiphong site, offering employment opportunities to the local community, especially in the fields of engineering and production, supporting the local economy.

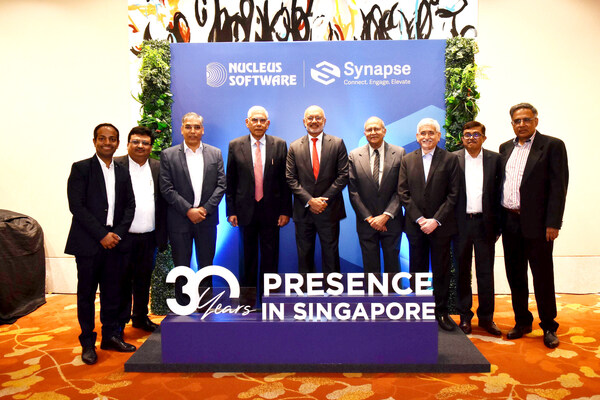

"The investment of approximately 55 million Euro in our new site in Haiphong is an important milestone in our strategy to regionalise production and optimise our supply chains," said Dr. Norman Goldberg, CEO of tesa. He attended the official opening ceremony that included a traditional performance as a symbol of good luck and a site tour. "My sincere gratitude not only to the passionate and committed tesa team, but also to the authorities in Haiphong, all our construction partners and to the German ambassador, for your much appreciated support throughout this entire project."

Another milestone in tesa's sustainability agenda: LEED Gold Certification in progress

tesa has made sustainability a priority and is working with great speed on this important transformation. This involves both the rapid reduction of emissions, a significant improvement in the sustainability of production, products and packaging, as well as responsible procurement. In the coming years, tesa will be making substantial investments in environmentally friendly conversion and further development of production at its plants. About 50 percent of the products to be manufactured at the tesa site Haiphong are water-based adhesives. A photovoltaic installation is to be installed and will cover about 10 percent of the yearly energy consumption at the site. Paired with a rainwater treatment plan, this will assist in obtaining LEED Gold Standard certification, demonstrating tesa's commitment to sustainability and environmental responsibility.

"This ambition is a testament to our efforts to minimise our ecological footprint by utilising sustainable manufacturing practices while delivering high-quality products to our customers," comments Stefan Schmidt, Head of tesa Supply Network, responsible for logistics and production at tesa worldwide. "I am sure our investment pays off and our customers appreciate the fast and flexible delivery."

You can find this press release and image material here.

Watch the video of the opening ceremony here.

About tesa SE

As a multinational company, tesa develops innovative adhesive tapes and self-adhesive product solutions for various industries, commercial customers and end consumers. There are already more than 7,000 tesa adhesive solutions that help improve the work, products or lives of our customers. Today, the focus is on sustainability and energy-saving processes. tesa invests in the development of environmentally friendly products and solvent-free manufacture processes as well as in the use of renewable energy sources at its locations.

tesa is active in 100 countries and operates plants in Germany, Italy, China, the USA and Vietnam. Around three quarters of the tesa Group's sales (2022: EUR 1.7 billion euro) are generated by applications for industries. Together with its international clients, tesa develops innovations that are customised at product and process level.

Already more than 130 tesa tapes may be installed in an electric car and over 70 in a smartphone. In the printing and construction industries tesa is penetrating new segments and countries with its specialised adhesive tapes. The company generates almost one quarter of its sales with products for end consumers and professional craftsmen. 300 applications, such as the legendary tesafilm®, make life easier or, when it comes to insect protection, even make it a bit more pleasant. tesa counts among the world's leading manufacturers of adhesive solutions. Since 2001, tesa SE is an independent 100% affiliate of Beiersdorf AG (i.e., NIVEA, Eucerin, la prairie) with approximately 5,000 employees today.

1 year ago

247

1 year ago

247

English (United States)

English (United States)